Last Updated: 04/24/2025 1:44 AM

The following table lists all the components that make up the document.

Replace SCA-775 Single Channel Analyzer (SCA) Module.

Coordinate site access with system operators

7264 - 1401 - Establish Initial Conditions; Remark:

1401 - Establish Initial Conditions

Establish Initial Conditions

7823 - 7592 - Inform system operators; Remark:

7592 - Inform system operators

Inform system operators

7824 - 7676 - Brief system operators on expected work, duration, anticipated alarms, and fa...; Remark:7677

7676 - Brief system operators on expected work, duration, anticipated alarms, and fa...

Brief system operators on expected work, duration, anticipated alarms, and fault indications before starting work

7677 - Operators should expect numerous fault indications and alarms during procedur...

Operators should expect numerous fault indications and alarms during procedure.

7847 - 7594 - Close lane and set up barriers to establish a safety watch; Remark:7846

7678 - Warning : Traffic should temporarily be rerouted or halted during conduction of this pr...

Traffic should temporarily be rerouted or halted during conduction of this procedure to ensure maintenance provider safety and prevent unscreened conveyances from passing.

7594 - Close lane and set up barriers to establish a safety watch

Close lane and set up barriers to establish a safety watch

7846 - Orange safety cones (traffic control) or equivalent per site-specific safety ...

Orange safety cones (traffic control) or equivalent per site-specific safety requirements.

7270 - 7235 - Power off RPM; Remark:7236

7235 - Power off RPM

Power off RPM

7236 - Move LD-260 switch to OFF position. The PWR ON

Move LD-260 switch to OFF position. The PWR ON LED will turn off.

7850 - 7848 - Removal of SCA-775 Module; Remark:

7848 - Removal of SCA-775 Module

Removal of SCA-775 Module

7852 - 7849 - Disconnect two cables on bottom of SCA-775 module; Remark:7851

7849 - Disconnect two cables on bottom of SCA-775 module

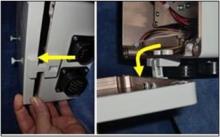

Disconnect two cables on bottom of SCA-775 module

7851 - Connectors are disconnected by turning lock ring multiple times and then pull...

Connectors are disconnected by turning lock ring multiple times and then pulling straight down.

7855 - 7853 - Disconnect all BNC and miniature high voltage (MHV) cables on top of SCA-775 ...; Remark:7854

7792 - Note : It is good engineering practice to ensure all cables and connectors are label...

It is good engineering practice to ensure all cables and connectors are labeled before disconnecting them.

7853 - Disconnect all BNC and miniature high voltage (MHV) cables on top of SCA-775 ...

Disconnect all BNC and miniature high voltage (MHV) cables on top of SCA-775 module

7854 - BNC Connectors

7857 - 7856 - Loosen screws in each corner (4) using medium Phillips screwdriver, and open ...; Remark:7797

7795 - Caution : If you rotate cover of the SCA-775 down without first pulling out from the bo...

If you rotate cover of the SCA-775 down without first pulling out from the box, the hinge will break.

7856 - Loosen screws in each corner (4) using medium Phillips screwdriver, and open ...

Loosen screws in each corner (4) using medium Phillips screwdriver, and open SCA-775 controller module

7797 - Normally the cover screws are captured and should not come out of cover. ...

Normally the cover screws are captured and should not come out of cover.

9467 - To prevent breaking the hinge on the module / door, once the retainer screws ...

To prevent breaking the hinge on the module / door, once the retainer screws are loosened, take care to gently pull the bottom of the cover away from the module approximately ¼ʺ before letting the door open.

7861 - 7859 - Remove 4 mounting screws; Remark:7860

7858 - Note : Most replaceable bit type screwdrivers will be too large in diameter to fit i...

Most replaceable bit type screwdrivers will be too large in diameter to fit into the hole.

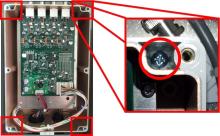

7859 - Remove 4 mounting screws

Remove 4 mounting screws

7860 - The screws to be removed are located in the bottom of the irregularly shaped ...

The screws to be removed are located in the bottom of the irregularly shaped hole next to the round hole. Insert the long shaft small Phillips screwdriver into each of the four corner pockets and loosen/remove screws.

7863 - 7862 - Remove SCA-775 module from back plate; Remark:

7862 - Remove SCA-775 module from back plate

Remove SCA-775 module from back plate

3397 - 3395 - Označte chybný komponent; Remark:3396

3395 - Označte chybný komponent

Označte chybný komponent

3396 - Použite štítok alebo pásku. Uveďte dátum odstránenia, opis príznakov zlyhania, k...

Použite štítok alebo pásku. Uveďte dátum odstránenia, opis príznakov zlyhania, krajinu, miesto a číslo/počet jazdných pruhov. Majte k dispozícii časti príručky alebo zmluvné požiadavky NSDD.

7865 - 7864 - Install New SCA-775 Module; Remark:

7864 - Install New SCA-775 Module

Install New SCA-775 Module

7868 - 7866 - Reinstall all four corner screws to mount replacement module; Remark:7867

7866 - Reinstall all four corner screws to mount replacement module

Reinstall all four corner screws to mount replacement module

7867 - Install all screws loosely at first to facillitate easy mounting, then gently...

Install all screws loosely at first to facillitate easy mounting, then gently but firmly tighten all four screws.

7879 - 7878 - Reattach two connectors on bottom of SCA-775 module; Remark:7870

7878 - Reattach two connectors on bottom of SCA-775 module

Reattach two connectors on bottom of SCA-775 module

7870 - The cable connectors are different sizes and keyed so they cannot be reinstal...

The cable connectors are different sizes and keyed so they cannot be reinstalled incorrectly.

7874 - 7872 - Reconnect BNC and MHV cables on top of SCA-775 module; Remark:7873

7811 - Caution : Proper connection of cables is critical.

Proper connection of cables is critical.

7872 - Reconnect BNC and MHV cables on top of SCA-775 module

Reconnect BNC and MHV cables on top of SCA-775 module

7873 - Verify each cable is connected to the appropriate connector.

Verify each cable is connected to the appropriate connector.

7837 - 7814 - Close SCA-775 module cover and tighten 4 screws; Remark:7815

7814 - Close SCA-775 module cover and tighten 4 screws

Close SCA-775 module cover and tighten 4 screws

7815 - If the follow-on alignment and functional compliance test procedures are to b...

If the follow-on alignment and functional compliance test procedures are to be completed immediately, there is no need to close the SCA-775 module cover; if not, close the cover and tighten the screws.

7280 - 7250 - Power on RPM; Remark:7251

7250 - Power on RPM

Power on RPM

7251 - Move LD-260 switch to ON position. The LED PWR ON

Move LD-260 switch to ON position. The LED PWR ON will illuminate.

7281 - 7252 - Verify RPM start-up; Remark:7253

7252 - Verify RPM start-up

Verify RPM start-up

7253 - RPM will perform a power on self-test (POST) and collect a background radiati...

RPM will perform a power on self-test (POST) and collect a background radiation measurement.

7279 - 7249 - Return equipment to normal operating condition; Remark:

7249 - Return equipment to normal operating condition

Return equipment to normal operating condition

7840 - 7816 - Perform electronic alignment; Remark:7817

7816 - Perform electronic alignment

Perform electronic alignment

7817 - DET-RPM-RAP-CM01, RPM Electronic Alignment Procedure.

DET-RPM-RAP-CM01, RPM Electronic Alignment Procedure.

7842 - 7820 - Inform system operators upon completion of maintenance action; Remark:

7820 - Inform system operators upon completion of maintenance action

Inform system operators upon completion of maintenance action

322 - 321 - Zdokumentujte postupy údržby; Remark:

321 - Zdokumentujte postupy údržby

Zdokumentujte postupy údržby

2869 - 2585 - Zdokumentujte vykonané činnosti údržby; Remark:2866

2585 - Zdokumentujte vykonané činnosti údržby

Zdokumentujte vykonané činnosti údržby

2866 - Zaznamenajte pozorovania a výsledky pre správu o nápravnej údržbe.

Zaznamenajte pozorovania a výsledky pre správu o nápravnej údržbe.

4706 - 4705 - Submit report; Remark:4864

4705 - Submit report

Submit report

4864 - As specified by management or contractual obligations.

As specified by management or contractual obligations.