Last Updated: 06/12/2025 1:44 AM

The following table lists all the components that make up the document.

Cleaning and inspection of Rapiscan radiation portal monitor (RPM).

30 Minutes per lane

Coordinate site access with radiation detection system operators

1402 - 7927 - Establish Initial Conditions; Remark:

7927 - Establish Initial Conditions

Establish Initial Conditions

7579 - 7577 - Brief operators on expected work, duration, anticipated fault indicators, and...; Remark:7576

7577 - Brief operators on expected work, duration, anticipated fault indicators, and...

Brief operators on expected work, duration, anticipated fault indicators, and arrange lane closures before starting work.

7576 - Alarms/faults: Operators should expect to receive tamper (TT) fault indicatio...

Alarms/faults: Operators should expect to receive tamper (TT) fault indications upon cabinet opening, loss of communications to affected RPM during procedure, and tamper clear (TC) indications upon closure of cabinet.

7574 - 7572 - Close lane and set up barriers.; Remark:7571

7578 - Warning : Vehicle, and/or pedestrian traffic should temporarily be rerouted or halted d...

Vehicle, and/or pedestrian traffic should temporarily be rerouted or halted during conduct of this procedure to ensure maintenance operator safety and prevent unscreened conveyances from passing through checkpoint.

7572 - Close lane and set up barriers.

Close lane and set up barriers.

7571 - Use orange safety cones or equivalent based on site-specific safety practices...

Use orange safety cones or equivalent based on site-specific safety practices.

7588 - 7587 - Clean and inspect RPM cabinet exterior; Remark:

7573 - Note : Perform and document each step in this procedure on a Rapiscan RPM Cleaning a...

Perform and document each step in this procedure on a Rapiscan RPM Cleaning and Inspection Checklist.

7575 - Reminder : All discrepancies noted during the performance of this procedure should be co...

All discrepancies noted during the performance of this procedure should be corrected immediately, if possible, and documented fully on the RPM Cleaning and Inspection Checklist and routine maintenance report

7587 - Clean and inspect RPM cabinet exterior

Clean and inspect RPM cabinet exterior

7585 - 7583 - Inspect exterior for dents, scratches, rust, and bare metal; Remark:

7583 - Inspect exterior for dents, scratches, rust, and bare metal

Inspect exterior for dents, scratches, rust, and bare metal

7586 - 7582 - Lubricate hinges and keyholes; Remark:7581

7584 - Note : If rust or bare metal is found, take corrective action. See SLD_Technical Ser...

If rust or bare metal is found, take corrective action. See SLD_Technical Service Bulletin - Painting RPM Cabinets for Corrosion (2015-02-20).

7582 - Lubricate hinges and keyholes

Lubricate hinges and keyholes

7581 - Use of a dry graphite lubricant is recommended.

Use of a dry graphite lubricant is recommended.

7903 - 7902 - Inspect RPM and pedestal bolts and flanges; Remark:7901

7902 - Inspect RPM and pedestal bolts and flanges

Inspect RPM and pedestal bolts and flanges

7901 - If loose, tighten the bolts and flanges

If loose, tighten the bolts and flanges

7900 - 7898 - Clean and inspect RPM cabinet interior; Remark:

7899 - Warning : If standing water is present in the RPM cabinet interior, implement site-spec...

If standing water is present in the RPM cabinet interior, implement site-specific electrical safety procedures, if required.

7898 - Clean and inspect RPM cabinet interior

Clean and inspect RPM cabinet interior

7894 - 7893 - Inspect interior of RPM cabinets for dirt, debris, and signs of water; Remark:

7893 - Inspect interior of RPM cabinets for dirt, debris, and signs of water

Inspect interior of RPM cabinets for dirt, debris, and signs of water

7895 - 7892 - Inspect for cables and wires in neat condition and tied down; Remark:

7892 - Inspect for cables and wires in neat condition and tied down

Inspect for cables and wires in neat condition and tied down

7896 - 7891 - Inspect desiccant and replace if required; Remark:7890

7891 - Inspect desiccant and replace if required

Inspect desiccant and replace if required

7890 - Per DET-RPM-RAP-RM01.

Per DET-RPM-RAP-RM01.

7897 - 7889 - Inspect battery, cables, and connectors for corrosion and damage; Remark:7888

7889 - Inspect battery, cables, and connectors for corrosion and damage

Inspect battery, cables, and connectors for corrosion and damage

7888 - Check for swelling of the battery case and corrosion of battery connections; ...

Check for swelling of the battery case and corrosion of battery connections; correct if these conditions exist.

7887 - 7886 - Inspect RPM cabinet for moisture intrusion; Remark:

7886 - Inspect RPM cabinet for moisture intrusion

Inspect RPM cabinet for moisture intrusion

7885 - 7884 - Inspect RPM penetrations for integrity and moisture intrusion such as localiz...; Remark:7883

7884 - Inspect RPM penetrations for integrity and moisture intrusion such as localiz...

Inspect RPM penetrations for integrity and moisture intrusion such as localized rust

7883 - Panel 1 Check that the cabinet penetrations for the lights, speaker, a...

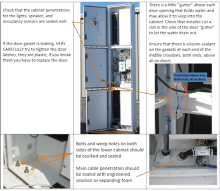

Panel 1

Check that the cabinet penetrations for the lights, speaker, and occupancy sensors are sealed well.

If the door gasket is leaking, VERY CAREFULLY try to tighten the door latches, they are plastic, if you break them you have to replace the door.

Panel 2

Bolts and weep holes on both sides of the lower cabinet should be caulked and sealed.

Main cable penetration should be sealed with engineered solution or expanding foam.

Panel 3

There is a little gutter above each door opening that holds water and may allow it to seep into the cabinet. Check that installer cut a slot in the side of the door gutter to let the water drain out.

Ensure that there is silicone sealant on the gaskets at each end of the middle crossbars, both ends, above all six doors.

Potential problem area. Both ends, all six doors.

7921 - 7920 - Inspect RPM door seals for leakage; Remark:7919

7920 - Inspect RPM door seals for leakage

Inspect RPM door seals for leakage

7919 - Localized deposit of dust on the inner side of the RPM door is indicative of ...

Localized deposit of dust on the inner side of the RPM door is indicative of a loose door or damaged seal.

7922 - 7918 - Inspect RPM internal surfaces and components for signs of rust and/or mildew; Remark:

7918 - Inspect RPM internal surfaces and components for signs of rust and/or mildew

Inspect RPM internal surfaces and components for signs of rust and/or mildew

7279 - 7249 - Return equipment to normal operating condition; Remark:

7249 - Return equipment to normal operating condition

Return equipment to normal operating condition

7911 - 7910 - Close doors and lock cabinets; Remark:

7910 - Close doors and lock cabinets

Close doors and lock cabinets

7912 - 7909 - Dispose of waste materials; Remark:

7909 - Dispose of waste materials

Dispose of waste materials

7913 - 7908 - Verify RPM is communicating with central alarm station and that all faults ar...; Remark:

7908 - Verify RPM is communicating with central alarm station and that all faults ar...

Verify RPM is communicating with central alarm station and that all faults are clear

7842 - 7820 - Inform system operators upon completion of maintenance action; Remark:

7820 - Inform system operators upon completion of maintenance action

Inform system operators upon completion of maintenance action

322 - 321 - Document maintenance actions; Remark:

321 - Document maintenance actions

Document maintenance actions

2869 - 2585 - Document maintenance performed; Remark:2866

2585 - Document maintenance performed

Document maintenance performed

2866 - Record observations, times, and results for the maintenance report.

Record observations, times, and results for the maintenance report.

4706 - 4705 - Submit report; Remark:4864

4705 - Submit report

Submit report

4864 - As specified by management or contractual obligations.

As specified by management or contractual obligations.