| Sensor Tech TA600 Radiation Pager |

Device

|

Published

|

10/28/2024 3:51 PM

|

| 7500 - 7489 - Remove existing battery; Remark: |

Procedure Step

|

Published

|

04/08/2025 4:30 PM

|

| 7489 - Remove existing battery |

Instruction

|

Published

|

06/03/2023 12:16 AM

|

| 11095 - 313 - Power off instrument; Remark:11093 |

Procedure Step

|

Published

|

10/01/2024 3:33 PM

|

| 313 - Power off instrument |

Instruction

|

Published

|

07/23/2021 2:41 PM

|

| 11093 - Rotate switch to OFF position. |

Remark

|

Published

|

10/01/2024 3:29 PM

|

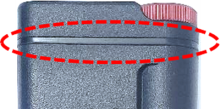

| 11094 - TA600 Rotate switch to OFF Position |

Remark

|

Published

|

10/01/2024 3:33 PM

|

| 11204 - 4370 - Locate battery cover; Remark:11202 |

Procedure Step

|

Published

|

10/01/2024 10:17 PM

|

| 4370 - Locate battery cover |

Instruction

|

Published

|

06/06/2022 9:11 PM

|

| 11202 - TA600 Locate battery cover |

Remark

|

Published

|

10/01/2024 10:16 PM

|

| 4369 - 4368 - Remove battery cover; Remark:11198 |

Procedure Step

|

Published

|

06/06/2022 9:13 PM

|

| 4368 - Remove battery cover |

Instruction

|

Published

|

06/06/2022 9:13 PM

|

| 11198 - Use a coin screwdriver, a medium #2 slotted screwdriver or a coin. Rotate counte... |

Remark

|

Published

|

10/01/2024 10:19 PM

|

| 11199 - TA600 Use a coin screwdriver, rotate counterclockwise |

Remark

|

Published

|

10/01/2024 10:22 PM

|

| 11200 - TA600 Remove battery cover, rotate counterclockwise |

Remark

|

Published

|

10/01/2024 10:23 PM

|

| 11201 - TA600 Use coin, rotate counterclockwise |

Remark

|

Published

|

10/01/2024 10:25 PM

|

| 11205 - 1816 - Remove battery; Remark:11196 |

Procedure Step

|

Published

|

10/01/2024 10:28 PM

|

| 1816 - Remove battery |

Instruction

|

Published

|

11/20/2020 9:29 AM

|

| 11196 - Retain battery. |

Remark

|

Published

|

10/01/2024 10:26 PM

|

| 11197 - TA600 Remove battery |

Remark

|

Published

|

10/01/2024 10:27 PM

|

| 11195 - 11194 - Remove faulty top housing; Remark: |

Procedure Step

|

Published

|

10/01/2024 10:29 PM

|

| 11194 - Remove faulty top housing |

Instruction

|

Published

|

10/01/2024 10:28 PM

|

| 11187 - 11185 - Remove label; Remark:11182 |

Procedure Step

|

Published

|

10/01/2024 10:33 PM

|

| 11186 - Caution : Do not mix components or circuit boards between instruments. Some components con... |

Annotation

|

Published

|

10/01/2024 10:29 PM

|

| 11185 - Remove label |

Instruction

|

Published

|

10/01/2024 10:30 PM

|

| 11182 - Use tweezers or a sharp blade to pry up the label using the speaker holes or ... |

Remark

|

Published

|

10/01/2024 10:30 PM

|

| 11183 - TA600 Remove label with tweezers |

Remark

|

Published

|

10/01/2024 10:32 PM

|

| 11184 - TA600 Remove label with sharp blade |

Remark

|

Published

|

10/01/2024 10:33 PM

|

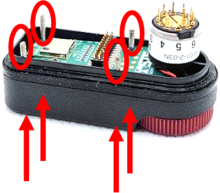

| 11188 - 11181 - Remove four enclosure screws and washers; Remark:11178 |

Procedure Step

|

Published

|

10/01/2024 10:37 PM

|

| 11181 - Remove four enclosure screws and washers |

Instruction

|

Published

|

10/01/2024 10:33 PM

|

| 11178 - Use 0.05-in. hex driver. Retain screws and washers. Washers might be difficult t... |

Remark

|

Published

|

10/01/2024 10:34 PM

|

| 11179 - TA600 Remove four screws |

Remark

|

Published

|

10/01/2024 10:35 PM

|

| 11180 - TA600 Retain screws and washers |

Remark

|

Published

|

10/01/2024 10:37 PM

|

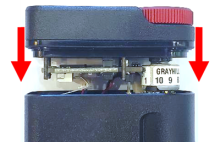

| 11189 - 6177 - Separate top and bottom enclosures; Remark:11176 |

Procedure Step

|

Published

|

10/01/2024 10:39 PM

|

| 11177 - Caution : Wires are still connected. Do not strain black and red wires. They can easily br... |

Annotation

|

Published

|

10/01/2024 10:37 PM

|

| 6177 - Separate top and bottom enclosures |

Instruction

|

Published

|

11/19/2022 5:55 PM

|

| 11176 - TA600 Separate top and bottom enclosures |

Remark

|

Published

|

10/01/2024 10:39 PM

|

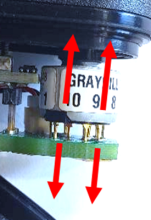

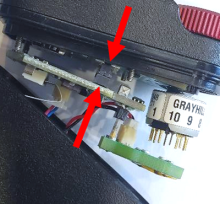

| 11190 - 11174 - Disconnect rotary switch board; Remark:11172 |

Procedure Step

|

Published

|

10/01/2024 10:45 PM

|

| 11175 - Caution : Avoid bending or breaking switch pins. |

Annotation

|

Published

|

10/01/2024 10:43 PM

|

| 11174 - Disconnect rotary switch board |

Instruction

|

Published

|

10/01/2024 10:43 PM

|

| 11172 - Carefully wiggle rotary switch board to remove it from switch. |

Remark

|

Published

|

10/01/2024 10:43 PM

|

| 11173 - TA600 Disconnect rotary switch board |

Remark

|

Published

|

10/01/2024 10:45 PM

|

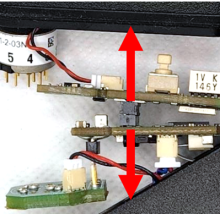

| 11191 - 11171 - Separate circuit boards; Remark:11169 |

Procedure Step

|

Published

|

10/01/2024 10:48 PM

|

| 11171 - Separate circuit boards |

Instruction

|

Published

|

10/01/2024 10:45 PM

|

| 11169 - Carefully wiggle boards to unplug the socket that holds boards together. |

Remark

|

Published

|

10/01/2024 10:45 PM

|

| 11170 - TA600 Separate circuit boards |

Remark

|

Published

|

10/01/2024 10:46 PM

|

| 11192 - 11168 - Disconnect piezo connector; Remark:11166 |

Procedure Step

|

Published

|

10/01/2024 10:50 PM

|

| 11168 - Disconnect piezo connector |

Instruction

|

Published

|

10/01/2024 10:49 PM

|

| 11166 - Retain circuit boards for reinstallation. |

Remark

|

Published

|

10/01/2024 10:49 PM

|

| 11167 - TA600 Disconnect piezo connector |

Remark

|

Published

|

10/01/2024 10:50 PM

|

| 3397 - 3395 - Label faulty component; Remark:3396 |

Procedure Step

|

Published

|

07/21/2024 6:59 AM

|

| 3395 - Label faulty component |

Instruction

|

Published

|

08/07/2021 11:07 AM

|

| 3396 - Use tag or tape. Include date of removal, description of failure symptoms, co... |

Remark

|

Published

|

08/09/2021 11:35 AM

|

| 11162 - 11161 - Install new top housing; Remark: |

Procedure Step

|

Published

|

10/01/2024 10:53 PM

|

| 11161 - Install new top housing |

Instruction

|

Published

|

10/01/2024 10:53 PM

|

| 11156 - 11155 - Connect piezo connector; Remark:11153 |

Procedure Step

|

Published

|

10/01/2024 10:55 PM

|

| 11155 - Connect piezo connector |

Instruction

|

Published

|

10/01/2024 10:54 PM

|

| 11153 - Use new top housing. |

Remark

|

Published

|

10/01/2024 10:54 PM

|

| 11154 - TA600 Use New Top Housing |

Remark

|

Published

|

10/01/2024 10:55 PM

|

| 11157 - 11152 - Insert PCBA into top housing; Remark:11149 |

Procedure Step

|

Published

|

10/01/2024 10:58 PM

|

| 11152 - Insert PCBA into top housing |

Instruction

|

Published

|

10/01/2024 10:55 PM

|

| 11149 - TA600 Insert PCBA into top housing |

Remark

|

Published

|

10/01/2024 10:56 PM

|

| 11150 - Route wires under rotary switch connector. Wires should not be coiled up on piez... |

Remark

|

Published

|

10/01/2024 10:57 PM

|

| 11151 - TA600 Route wires under rotary switch |

Remark

|

Published

|

10/01/2024 10:58 PM

|

| 11158 - 11148 - Insert four enclosure screws and washers; Remark:11145 |

Procedure Step

|

Published

|

10/01/2024 11:01 PM

|

| 11148 - Insert four enclosure screws and washers |

Instruction

|

Published

|

10/01/2024 10:59 PM

|

| 11145 - TA600 Insert four enclosure screws and washers |

Remark

|

Published

|

10/01/2024 11:00 PM

|

| 11146 - Verify screws do not interfere with piezo wires. |

Remark

|

Published

|

10/01/2024 11:00 PM

|

| 11147 - TA600 Verify screws do not interfere with piezo wires |

Remark

|

Published

|

10/01/2024 11:01 PM

|

| 11159 - 11143 - Connect PCBAs; Remark:11141 |

Procedure Step

|

Published

|

10/01/2024 11:05 PM

|

| 11144 - Caution : Verify the connectors are aligned correctly. Misalignment of this connector is c... |

Annotation

|

Published

|

10/01/2024 11:01 PM

|

| 11143 - Connect PCBAs |

Instruction

|

Published

|

10/01/2024 11:02 PM

|

| 11141 - Carefully line up the pins with the sockets and press firmly. |

Remark

|

Published

|

10/01/2024 11:02 PM

|

| 11142 - TA600 Connect PCBAs line up pins with sockets |

Remark

|

Published

|

10/01/2024 11:05 PM

|

| 11160 - 11140 - Connect rotary switch board; Remark:11141 |

Procedure Step

|

Published

|

10/01/2024 11:06 PM

|

| 11140 - Connect rotary switch board |

Instruction

|

Published

|

10/01/2024 11:05 PM

|

| 11237 - TA600 Connect rotary switch board |

Remark

|

Published

|

10/01/2024 11:09 PM

|

| 11238 - 11235 - Place top housing on bottom housing; Remark:11233 |

Procedure Step

|

Published

|

10/01/2024 11:12 PM

|

| 11236 - Caution : Verify all wires are inside instrument. Verify wires do not interfere ... |

Annotation

|

Published

|

10/01/2024 11:10 PM

|

| 11235 - Place top housing on bottom housing |

Instruction

|

Published

|

10/01/2024 11:10 PM

|

| 11233 - Route wire to avoid enclosure screws. |

Remark

|

Published

|

10/01/2024 11:10 PM

|

| 11234 - TA600 Place top housing, route wire to avoid screws |

Remark

|

Published

|

10/01/2024 11:12 PM

|

| 11239 - 11232 - Evenly tighten enclosure screws; Remark:11228 |

Procedure Step

|

Published

|

10/01/2024 11:18 PM

|

| 569 - Caution : Do not overtighten screws. |

Annotation

|

Published

|

06/16/2021 2:31 PM

|

| 11232 - Evenly tighten enclosure screws |

Instruction

|

Published

|

10/01/2024 11:13 PM

|

| 11228 - Evenly tighten screws until the gasket is lightly compressed. It is recommended ... |

Remark

|

Published

|

10/01/2024 11:13 PM

|

| 11229 - TA600 Evenly tighten screws |

Remark

|

Published

|

10/01/2024 11:14 PM

|

| 11230 - TA600 Tighten screws until gasket compressed |

Remark

|

Published

|

10/01/2024 11:16 PM

|

| 11231 - |

Remark

|

Published

|

10/01/2024 11:18 PM

|

| 11240 - 11227 - Verify enclosure screws are tightened correctly; Remark:11225 |

Procedure Step

|

Published

|

10/01/2024 11:20 PM

|

| 11227 - Verify enclosure screws are tightened correctly |

Instruction

|

Published

|

10/01/2024 11:18 PM

|

| 11225 - 1 – Not tight enough; gap between gasket and housing 2 – Too tight... |

Remark

|

Published

|

10/01/2024 11:19 PM

|

| 11226 - TA600 Verify enclosure screws tightened correctly |

Remark

|

Published

|

10/01/2024 11:20 PM

|

| 11224 - 11223 - Replace battery; Remark: |

Procedure Step

|

Published

|

10/01/2024 11:21 PM

|

| 11223 - Replace battery |

Instruction

|

Published

|

10/01/2024 11:21 PM

|

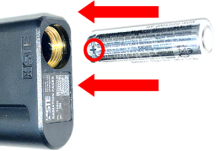

| 11221 - 11220 - Insert battery; Remark:11218 |

Procedure Step

|

Published

|

10/01/2024 11:23 PM

|

| 11220 - Insert battery |

Instruction

|

Published

|

10/01/2024 11:21 PM

|

| 11218 - Insert positive (+) terminal first. |

Remark

|

Published

|

10/01/2024 11:21 PM

|

| 11219 - TA600 Insert battery |

Remark

|

Published

|

10/01/2024 11:22 PM

|

| 11222 - 4354 - Reinstall battery cover; Remark:11215 |

Procedure Step

|

Published

|

10/01/2024 11:28 PM

|

| 4354 - Reinstall battery cover |

Instruction

|

Published

|

06/06/2022 9:24 PM

|

| 11215 - Use a coin screwdriver, a medium #2 slotted screwdriver or a coin. Rotate clockw... |

Remark

|

Published

|

10/01/2024 11:25 PM

|

| 11216 - TA600 Use a coin screwdriver, rotate clockwise |

Remark

|

Published

|

10/01/2024 11:26 PM

|

| 11217 - TA600 Use a slotted screwdriver, or coin, rotate clockwise |

Remark

|

Published

|

10/01/2024 11:28 PM

|

| 11214 - 11213 - Verify instrument is operational; Remark: |

Procedure Step

|

Published

|

10/01/2024 11:29 PM

|

| 11213 - Verify instrument is operational |

Instruction

|

Published

|

10/01/2024 11:29 PM

|

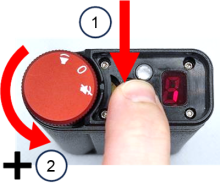

| 11212 - 11211 - Initiate self-test; Remark:11207 |

Procedure Step

|

Published

|

10/01/2024 11:37 PM

|

| 11211 - Initiate self-test |

Instruction

|

Published

|

10/01/2024 11:30 PM

|

| 11207 - 1 – Hold down display button. 2 – While holding display button, tu... |

Remark

|

Published

|

10/01/2024 11:30 PM

|

| 11208 - TA600 Initiate Self-test Hold Turn to Vibrate mode |

Remark

|

Published

|

10/01/2024 11:31 PM

|

| 11209 - 3 – Release display button after LED flashes blue |

Remark

|

Published

|

10/01/2024 11:32 PM

|

| 11210 - TA600 Initiate Self-test Release After Blue LED |

Remark

|

Published

|

10/01/2024 11:36 PM

|

| 11255 - 11254 - Observe self-test; Remark:11244 |

Procedure Step

|

Published

|

10/02/2024 12:12 AM

|

| 11254 - Observe self-test |

Instruction

|

Published

|

10/01/2024 11:51 PM

|

| 11244 - The instrument will go through several routines in rapid succession. L... |

Remark

|

Published

|

10/01/2024 11:51 PM

|

| 11245 - TA600 Observe self-test LED will rapidly flash |

Remark

|

Published

|

10/02/2024 12:03 AM

|

| 11246 - All segments of segmented display will illuminate sequentially. |

Remark

|

Published

|

10/02/2024 12:03 AM

|

| 11247 - TA600 Observe Self-test Display will illuminate sequentially |

Remark

|

Published

|

10/02/2024 12:04 AM

|

| 11248 - Instrument will beep |

Remark

|

Published

|

10/02/2024 12:05 AM

|

| 11249 - TA600 Observe Self-test, Instrument will beep |

Remark

|

Published

|

10/02/2024 12:06 AM

|

| 11250 - Instrument will vibrate |

Remark

|

Published

|

10/02/2024 12:06 AM

|

| 11251 - TA600 Observe Self-test, Instrument will vibrate |

Remark

|

Published

|

10/02/2024 12:08 AM

|

| 11252 - Middle LED segment will flash and disappear |

Remark

|

Published

|

10/02/2024 12:08 AM

|

| 11253 - TA600 Observe Self-test, middle LED segment will flash and disappear |

Remark

|

Published

|

10/02/2024 12:11 AM

|

| 11256 - 11243 - Verify successful self-test; Remark:11241 |

Procedure Step

|

Published

|

10/02/2024 12:14 AM

|

| 11243 - Verify successful self-test |

Instruction

|

Published

|

10/02/2024 12:12 AM

|

| 11241 - The self-test is successful if actions were observed. If the middle LED segment ... |

Remark

|

Published

|

10/02/2024 12:12 AM

|

| 11242 - TA600 self-test is successful if actions were observed |

Remark

|

Published

|

10/02/2024 12:14 AM

|

| 11272 - 319 - Perform operational test; Remark:11271 |

Procedure Step

|

Published

|

10/02/2024 12:19 AM

|

| 319 - Perform operational test |

Instruction

|

Published

|

06/10/2021 8:31 PM

|

| 11271 - DET-HHD-STE-TA6-RM01, TA600 Operational Test |

Remark

|

Published

|

10/02/2024 12:19 AM

|

| 11270 - 11269 - Complete Assembly; Remark: |

Procedure Step

|

Published

|

10/02/2024 12:21 AM

|

| 11269 - Complete Assembly |

Instruction

|

Published

|

10/02/2024 12:20 AM

|

| 11265 - 313 - Power off instrument; Remark:11093 |

Procedure Step

|

Published

|

10/02/2024 12:23 AM

|

| 11266 - 11073 - Clean top housing; Remark:11264 |

Procedure Step

|

Published

|

10/02/2024 12:24 AM

|

| 11073 - Clean top housing |

Instruction

|

Published

|

10/01/2024 7:12 PM

|

| 11264 - Use cotton swab with alcohol. Carefully clean top of instrument. This will remov... |

Remark

|

Published

|

10/02/2024 12:24 AM

|

| 11273 - TA600 Clean top housing |

Remark

|

Published

|

10/02/2024 12:47 AM

|

| 11268 - 11260 - Apply enclosure label; Remark:11258 |

Procedure Step

|

Published

|

10/02/2024 12:29 AM

|

| 11260 - Apply enclosure label |

Instruction

|

Published

|

10/02/2024 12:27 AM

|

| 11258 - Remove label backing. Align label on top housing. |

Remark

|

Published

|

10/02/2024 12:27 AM

|

| 11259 - TA600 Apply enclosure label |

Remark

|

Published

|

10/02/2024 12:29 AM

|

| 322 - 321 - Document maintenance actions; Remark: |

Procedure Step

|

Published

|

06/17/2021 9:49 AM

|

| 321 - Document maintenance actions |

Instruction

|

Published

|

04/21/2025 11:19 AM

|

| 2869 - 2585 - Document maintenance performed; Remark:2866 |

Procedure Step

|

Published

|

06/18/2021 5:58 PM

|

| 2585 - Document maintenance performed |

Instruction

|

Published

|

07/09/2021 12:15 PM

|

| 2866 - Record observations, times, and results for the maintenance report. |

Remark

|

Published

|

04/21/2025 11:39 AM

|

| 4706 - 4705 - Submit report; Remark:4864 |

Procedure Step

|

Published

|

06/29/2022 9:50 AM

|

| 4705 - Submit report |

Instruction

|

Published

|

06/29/2022 9:50 AM

|

| 4864 - As specified by management or contractual obligations. |

Remark

|

Published

|

07/28/2022 1:36 PM

|

| Corrective Maintenance Procedure |

Document Type

|

Published

|

03/02/2020 3:32 PM

|

| hour |

Duration

|

Published

|

05/26/2022 11:41 AM

|

| As Needed |

Frequency

|

Published

|

04/01/2020 11:36 AM

|

| Display button is difficult to press |

Frequency

|

Published

|

10/02/2024 6:09 AM

|

| Power knob is difficult to turn |

Frequency

|

Published

|

10/02/2024 6:09 AM

|

| Caution |

Annotation Type

|

Published

|

03/02/2020 3:24 PM

|

| Technician 2 |

Skill Level

|

Published

|

04/09/2020 1:17 AM

|

| Coin screwdriver (STE Part# 8125-9-45) |

Tools

|

Published

|

10/02/2024 6:14 AM

|

| Tweezers |

Tools

|

Published

|

08/30/2022 4:28 PM

|

| 0.05-in. hex driver |

Replacement Parts

|

Published

|

10/01/2024 7:27 PM

|

| TA600 Verify Knob Alignment |

Resim

|

Published

|

10/01/2024 7:27 PM

|

| TA600 Locate battery cover |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Use a coin screwdriver, rotate counterclockwise |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Remove battery cover, rotate counterclockwise |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Use coin, rotate counterclockwise |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Remove battery |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Remove label with tweezers |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Remove label with sharp blade |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Remove four screws |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Retain screws and washers |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Separate top and bottom enclosures |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Disconnect rotary switch board |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Separate circuit boards |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Disconnect piezo connector |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Use New Top Housing |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Insert PCBA into top housing |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Route wires under rotary switch |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Insert four enclosure screws and washers |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Verify screws do not interfere with piezo wires |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Connect PCBAs line up pins with sockets |

Resim

|

Published

|

10/01/2024 11:06 PM

|

| TA600 Connect rotary switch board |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600 Place top housing, route wire to avoid screws |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600 Evenly tighten screws |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600 Tighten screws until gasket compressed |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600 Gasket is lightly compressed |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600_Verify_enclosure_screws_tightened_correctly_0.png |

Resim

|

Published

|

10/02/2024 9:59 AM

|

| TA600 Insert battery |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600 Use a coin screwdriver, rotate clockwise |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600 Use a slotted screwdriver, or coin, rotate clockwise |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600 Initiate Self-test Hold Turn to Vibrate mode |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600 Initiate Self-test Release After Blue LED |

Resim

|

Published

|

10/01/2024 11:37 PM

|

| TA600 Observe self-test LED will rapidly flash |

Resim

|

Published

|

10/02/2024 12:14 AM

|

| TA600 Observe Self-test Display will illuminate sequentially |

Resim

|

Published

|

10/02/2024 12:14 AM

|

| TA600 Observe Self-test, Instrument will beep |

Resim

|

Published

|

10/02/2024 12:14 AM

|

| TA600 Observe Self-test, Instrument will vibrate |

Resim

|

Published

|

10/02/2024 12:14 AM

|

| TA600 Observe Self-test |

Resim

|

Published

|

10/02/2024 12:14 AM

|

| TA600 Clean top housing |

Resim

|

Published

|

10/02/2024 12:30 AM

|

| TA600 Apply enclosure label |

Resim

|

Published

|

10/02/2024 12:30 AM

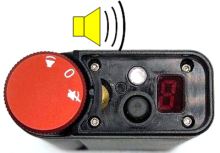

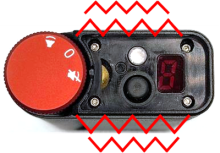

|