Last Updated: 04/24/2025 1:44 AM

The following table lists all the components that make up the document.

Install the ThetaController to replace both the GE VersaMax Nano Controller, Model# IC200NDR010 (Rapiscan Part #6661N) and the RS232 to RS485 Converter (Rapiscan Part #2725A) on the radiation portal monitor (RPM).

Verify Speed message

Prior to arrival, notify operators concerning expected work, duration, and anticipated alarms and fault indications.

Updated LD-260 Power on instructions and images to re-usable standard content.

1402 - 7927 - Başlangıç Koşullarını belirleyin; Remark:

7927 - Başlangıç Koşullarını belirleyin

Başlangıç Koşullarını belirleyin

7268 - 7231 - Close lane; Remark:7233

9053 - Warning : Traffic should temporarily be rerouted or halted during conduction of this pr...

Traffic should temporarily be rerouted or halted during conduction of this procedure to ensure maintenance provider safety and to prevent unscreened vehicles from passing.

7231 - Close lane

Close lane

7233 - Use orange safety (traffic control) cones to setup barriers. Practice establi...

Use orange safety (traffic control) cones to setup barriers. Practice established safety protocols.

7269 - 7232 - Open RPM door; Remark:7234

7232 - Open RPM door

Open RPM door

7234 - Open all doors needed to access components.

Open all doors needed to access components.

7454 - 7290 - Disable tamper switches; Remark:7416

7290 - Disable tamper switches

Disable tamper switches

7416 - Use a magnet to disable tamper switches for all open doors. Use adhesive tape...

Use a magnet to disable tamper switches for all open doors. Use adhesive tape to disable older mechanical switches.

8281 - 8280 - Disable both infrared occupancy sensors; Remark:8279

7351 - Note : It is good practice to verify all cables and connectors are labeled prior to ...

It is good practice to verify all cables and connectors are labeled prior to disconnection.

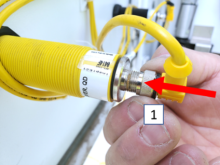

8280 - Disable both infrared occupancy sensors

Disable both infrared occupancy sensors

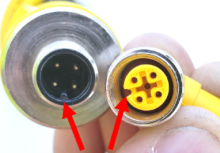

8279 - Verify sensors mounted in control pillar door are receivers

Verify sensors mounted in control pillar door are receivers

8287 - To disconnect sensor cable, turn collar counterclockwise and pull away from s...

To disconnect sensor cable, turn collar counterclockwise and pull away from sensor.

7270 - 7235 - Power off RPM; Remark:7236

7235 - Power off RPM

Power off RPM

7236 - Move LD-260 switch to OFF position. The PWR ON

Move LD-260 switch to OFF position. The PWR ON LED will turn off.

8344 - 8343 - Locate RS232 to RS485 Converter; Remark:8341

8343 - Locate RS232 to RS485 Converter

Locate RS232 to RS485 Converter

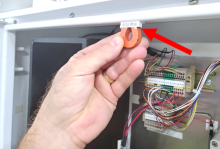

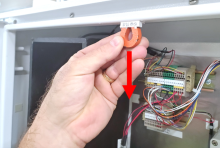

8341 - For vehicle monitors (VM-250), the converter is located behind the LD-260...

For vehicle monitors (VM-250), the converter is located behind the LD-260

8342 - For train monitors (TM-850), the converter is usually located in the electron...

For train monitors (TM-850), the converter is usually located in the electronics cabinet on the control pillar

8340 - 8339 - Uninstall LD-260 (VM-250 only); Remark:

8339 - Uninstall LD-260 (VM-250 only)

Uninstall LD-260 (VM-250 only)

7272 - 7238 - Disconnect three (3) connectors; Remark:7239

5291 - Note : It is good practice to verify all cables and connectors are labeled prior to ...

It is good practice to verify all cables and connectors are labeled prior to disconnection.

7238 - Disconnect three (3) connectors

Disconnect three (3) connectors

7239 - Needle nose pliers can be used to remove connectors.

8347 - 8346 - Remove two (2) mounting screws; Remark:8345

8346 - Remove two (2) mounting screws

Remove two (2) mounting screws

8345 - Use medium Phillips (PH2) screwdriver. Retain screws.

Use medium Phillips (PH2) screwdriver. Retain screws.

8338 - 8337 - Remove LD-260; Remark:8336

8337 - Remove LD-260

Remove LD-260

8336 - Retain part for reinstallation

Retain part for reinstallation

8351 - 8350 - Uninstall RS232 to RS485 converter; Remark:

8350 - Uninstall RS232 to RS485 converter

Uninstall RS232 to RS485 converter

8349 - 7293 - Disconnect RJ-45 Ethernet cable; Remark:8367

5291 - Note : It is good practice to verify all cables and connectors are labeled prior to ...

It is good practice to verify all cables and connectors are labeled prior to disconnection.

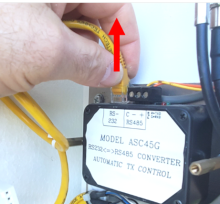

7293 - Disconnect RJ-45 Ethernet cable

Disconnect RJ-45 Ethernet cable

8367 -

8354 - 8353 - Disconnect power/signal connector; Remark:8352

8353 - Disconnect power/signal connector

Disconnect power/signal connector

8352 - Needle nose pliers may be used

Needle nose pliers may be used

8358 - 8357 - Remove mounting hardware; Remark:8356

8357 - Remove mounting hardware

Remove mounting hardware

8356 - For a VM-250, use Pliers. Retain hardware. For a TM-850, remove mounti...

For a VM-250, use Pliers. Retain hardware.

For a TM-850, remove mounting screws. Use medium Phillips (PH2) screwdriver. Retain screws.

8359 - 8355 - Remove RS232 to RS485 converter; Remark:

8355 - Remove RS232 to RS485 converter

Remove RS232 to RS485 converter

8366 - 8364 - Label component; Remark:8363

8365 - Note : This component is no longer required.

This component is no longer required.

8364 - Label component

Label component

8363 - Use a tag or tape. Include date of removal, description of failure symptoms, ...

Use a tag or tape. Include date of removal, description of failure symptoms, country, site, and lane number. Retain or dispose of component per Nuclear Smuggling Detection and Deterrence (NSDD) guidance or contractual requirements.

8362 - 8361 - Uninstall Nano Controller; Remark:

8361 - Uninstall Nano Controller

Uninstall Nano Controller

8370 - 8369 - Disconnect RJ-45 Ethernet cable; Remark:8368

5291 - Note : It is good practice to verify all cables and connectors are labeled prior to ...

It is good practice to verify all cables and connectors are labeled prior to disconnection.

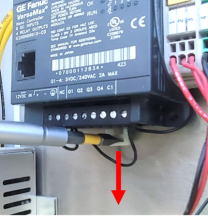

8369 - Disconnect RJ-45 Ethernet cable

Disconnect RJ-45 Ethernet cable

8368 -

8377 - 8376 - Disconnect occupancy sensor wires; Remark:8375

8376 - Disconnect occupancy sensor wires

Disconnect occupancy sensor wires

8375 - Use small slotted screwdriver. Remove wires from I1 terminal...

Use small slotted screwdriver. Remove wires from I1 terminal and I2 terminal.

8378 - 8374 - Disconnect power wires; Remark:8373

8374 - Disconnect power wires

Disconnect power wires

8373 - These wires go to Terminal Block 1 (TB1). Use small slotted screwdriver

These wires go to Terminal Block 1 (TB1). Use small slotted screwdriver

8379 - 8372 - Disconnect occupancy output wire; Remark:8371

8372 - Disconnect occupancy output wire

Disconnect occupancy output wire

8371 - Use small slotted screwdriver. Remove green wire from Q1 ter...

Use small slotted screwdriver. Remove green wire from Q1 terminal.

8383 - 8381 - Remove Nano Controller; Remark:8380

8382 - Note : Nano Controller installation may differ from configuration shown in this proc...

Nano Controller installation may differ from configuration shown in this procedure.

8381 - Remove Nano Controller

Remove Nano Controller

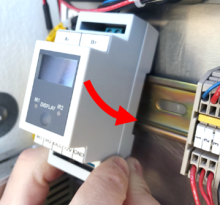

8380 - Use slotted screwdriver to pull down tab and rotate Nano Controller up. Use m...

Use slotted screwdriver to pull down tab and rotate Nano Controller up. Use medium Phillips (PH2) screwdriver if Nano Controller is mounted with screws.

8398 - 8396 - Label component; Remark:8395

8397 - Note : This component is no longer required

This component is no longer required

8396 - Label component

Label component

8395 - Use a tag or tape. Include date of removal, description of failure symptoms, ...

Use a tag or tape. Include date of removal, description of failure symptoms, country, site, and lane number. Retain or dispose of component per NSDD guidance or contractual requirements.

8394 - 8393 - Install ThetaController; Remark:

8393 - Install ThetaController

Install ThetaController

8390 - 8389 - Lower mounting tab; Remark:8388

8403 - Note : Depending on the RPM configuration, it may be easier to attach the ThetaContr...

Depending on the RPM configuration, it may be easier to attach the ThetaController to the mounting rail after all wiring is complete.

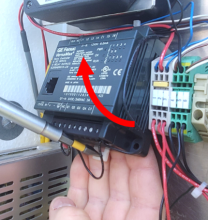

8389 - Lower mounting tab

Lower mounting tab

8388 - The tab on the back of the ThetaController must be in the DOWN position to in...

The tab on the back of the ThetaController must be in the DOWN position to install on the mounting rail.

8391 - 8387 - Set ThetaController in place; Remark:8386

8387 - Set ThetaController in place

Set ThetaController in place

8386 - Hook ThetaController to top of mounting rail and rotate down.

Hook ThetaController to top of mounting rail and rotate down.

8392 - 8385 - Lock mounting tab; Remark:8384

8385 - Lock mounting tab

Lock mounting tab

8384 - On bottom of ThetaController, push tab up to lock into place.

On bottom of ThetaController, push tab up to lock into place.

8404 - 8402 - Connect speed output wire to B+ terminal; Remark:8401

5553 - Caution : Correct placement of connectors and wiring is critical to proper operation.

Correct placement of connectors and wiring is critical to proper operation.

8402 - Connect speed output wire to B+ terminal

Connect speed output wire to B+ terminal

8401 - Remove wire from (+) terminal on RS232 to RS485 converter power/signal connec...

Remove wire from (+) terminal on RS232 to RS485 converter power/signal connector (usually orange color). The other end of this wire connects to terminal block 3 (TB3) at position 9. Use small slotted screwdriver to tighten wiring connections.

8405 - 8400 - Connect speed output wire to A- terminal; Remark:8399

8400 - Connect speed output wire to A- terminal

Connect speed output wire to A- terminal

8399 - Remove wire from (-) terminal on RS232 to RS485 converter power/signal connec...

Remove wire from (-) terminal on RS232 to RS485 converter power/signal connector (usually yellow color). The other end of this wire connects to TB3, position 10. Use small slotted screwdriver to tighten wiring connections

8415 - 8411 - Connect occupancy input to IR1 terminal; Remark:8410

8411 - Connect occupancy input to IR1 terminal

Connect occupancy input to IR1 terminal

8410 - Use wire from I1 terminal on Nano Controller (usually black color). This wire...

Use wire from I1 terminal on Nano Controller (usually black color). This wire comes from the black infrared occupancy sensor.

8416 - 8409 - Connect occupancy input to IR2 terminal; Remark:8408

8409 - Connect occupancy input to IR2 terminal

Connect occupancy input to IR2 terminal

8408 - Use wire from I2 terminal on Nano Controller (usually black color). This wire...

Use wire from I2 terminal on Nano Controller (usually black color). This wire comes from the yellow infrared occupancy sensor.

8417 - 8407 - Connect occupancy output to OCC terminal; Remark:8406

8407 - Connect occupancy output to OCC terminal

Connect occupancy output to OCC terminal

8406 - Use wire from Q1 terminal on Nano Controller (usually green color). The other...

Use wire from Q1 terminal on Nano Controller (usually green color). The other end of this wire connects to TB2, position 6.

8422 - 8419 - Connect power wire to 12V terminal; Remark:8418

8419 - Connect power wire to 12V terminal

Connect power wire to 12V terminal

8418 - Use wire from 12 VDC IN (+) terminal on the Nano Controller (usually red colo...

Use wire from 12 VDC IN (+) terminal on the Nano Controller (usually red color). The other end of this wire connects to TB2 between positions 16 and 20, which are all +12 VDC.

8423 - 8421 - Connect ground wire to GND terminal; Remark:8420

8421 - Connect ground wire to GND terminal

Connect ground wire to GND terminal

8420 - Use wire from 12 VDC IN (-) terminal on the Nano Controller (usually red colo...

Use wire from 12 VDC IN (-) terminal on the Nano Controller (usually red color). The other end of this wire connects to TB2 between positions 10 and 15, which are all grounded.

7279 - 7249 - Return equipment to normal operating condition; Remark:

7249 - Return equipment to normal operating condition

Return equipment to normal operating condition

7280 - 7250 - Power on RPM; Remark:7251

7250 - Power on RPM

Power on RPM

7251 - Move LD-260 switch to ON position. The LED PWR ON

Move LD-260 switch to ON position. The LED PWR ON will illuminate.

7468 - 7304 - Confirm RPM has restarted correctly; Remark:7487

7304 - Confirm RPM has restarted correctly

Confirm RPM has restarted correctly

7487 - The SC-770 controller will display "OK" following Power On Self-Test (POST) a...

The SC-770 controller will display "OK" following Power On Self-Test (POST) and background measurement.

7282 - 7254 - Confirm network connection; Remark:7255

7254 - Confirm network connection

Confirm network connection

7255 - Contact operators to confirm communications have been reestablished between RPM ...

8317 - 8316 - Enable both infrared occupancy sensors; Remark:8315

7263 - Caution : Correct placement of connectors and wiring is critical to proper operation.

Correct placement of connectors and wiring is critical to proper operation.

8316 - Enable both infrared occupancy sensors

Enable both infrared occupancy sensors

8315 - To reconnect sensor cable, align connectors, push towards sensor, and turn th...

To reconnect sensor cable, align connectors, push towards sensor, and turn the collar clockwise.

8433 - 8432 - Close all RPM doors; Remark:

8432 - Close all RPM doors

Close all RPM doors

8434 - 8431 - Generate speed message; Remark:8430

8431 - Generate speed message

Generate speed message

8430 - Stand to side of control pillar. Open door with infrared sensors.

Stand to side of control pillar. Open door with infrared sensors.

8435 - 8429 - Verify ThetaController response; Remark:8428

8429 - Verify ThetaController response

Verify ThetaController response

8428 - IR1 and IR2 will be illuminated

IR1 and IR2 will be illuminated

8436 - 8427 - Check speed value; Remark:8426

8427 - Check speed value

Check speed value

8426 - Press button to display speed information for latest occupancy on ThetaContro...

Press button to display speed information for latest occupancy on ThetaController.

8437 - 8425 - Verify speed message in CAS; Remark:8424

8425 - Verify speed message in CAS

Verify speed message in CAS

8424 - Contact CAS operator to verify “SP” appears in RAVEN [Radiation Alarm and...

Contact CAS operator to verify “SP” appears in RAVEN [Radiation Alarm and Video Event Notification] data stream and/or the daily file. Speed messages can also be viewed by connecting a computer to the SC-770 Ethernet output.

8318 - 7450 - Enable tamper switches; Remark:7348

7450 - Enable tamper switches

Enable tamper switches

7348 - Remove all magnets and/or adhesive tape from door switches.

Remove all magnets and/or adhesive tape from door switches.

7283 - 7256 - Close and lock all RPM doors; Remark:

7256 - Close and lock all RPM doors

Close and lock all RPM doors

7842 - 7820 - Inform system operators upon completion of maintenance action; Remark:

7820 - Inform system operators upon completion of maintenance action

Inform system operators upon completion of maintenance action

322 - 321 - Bakım İşlemlerini kaydedin; Remark:

321 - Bakım İşlemlerini kaydedin

Bakım İşlemlerini kaydedin

2869 - 2585 - Yapılan bakımı kaydedin; Remark:2866

2585 - Yapılan bakımı kaydedin

Yapılan bakımı kaydedin

2866 - Düzeltici Bakım Raporu için gözlemleri, zamanları ve sonuçları kaydedin.

Düzeltici Bakım Raporu için gözlemleri, zamanları ve sonuçları kaydedin.

4706 - 4705 - Submit report; Remark:4864

4705 - Submit report

Submit report

4864 - As specified by management or contractual obligations.

As specified by management or contractual obligations.