Last Updated: 04/25/2025 1:45 AM

The following table lists all the components that make up the document.

| Title | Type | Status | Last Updated |

|---|---|---|---|

| Sensor Tech TA600 Radiation Pager | Device

|

Published

|

10/28/2024 3:51 PM

|

| 11095 - 313 - Power off instrument; Remark:11093 | Procedure Step

|

Published

|

10/01/2024 3:33 PM

|

| 313 - Power off instrument | Instruction

|

Published

|

07/23/2021 2:41 PM

|

| 11093 - Rotate switch to OFF position. | Remark

|

Published

|

10/01/2024 3:29 PM

|

| 11094 - TA600 Rotate switch to OFF Position | Remark

|

Published

|

10/01/2024 3:33 PM

|

| 11092 - 11091 - Uninstall power knob; Remark: | Procedure Step

|

Published

|

10/01/2024 3:35 PM

|

| 11091 - Uninstall power knob | Instruction

|

Published

|

10/01/2024 3:35 PM

|

| 11089 - 11088 - Remove set screw; Remark:11084 | Procedure Step

|

Published

|

10/01/2024 5:04 PM

|

| 11088 - Remove set screw | Instruction

|

Published

|

10/01/2024 5:00 PM

|

| 11084 - Use 0.05-in. hex driver. Rotate counterclockwise. | Remark

|

Published

|

10/01/2024 5:00 PM

|

| 11085 - Remove set screw | Remark

|

Published

|

10/01/2024 5:02 PM

|

| 11086 - Retain set screw. | Remark

|

Published

|

10/01/2024 5:03 PM

|

| 11087 - Retain set screw | Remark

|

Published

|

10/01/2024 5:04 PM

|

| 11090 - 11083 - Remove knob; Remark:11079 | Procedure Step

|

Published

|

10/01/2024 7:11 PM

|

| 11083 - Remove knob | Instruction

|

Published

|

10/01/2024 5:05 PM

|

| 11079 - If needed, use small, slotted screwdriver. Carefully pry up the knob using small... | Remark

|

Published

|

10/01/2024 5:05 PM

|

| 11080 - TA600 Remove knob | Remark

|

Published

|

10/01/2024 7:08 PM

|

| 11081 - TA600 Carefully pry up the knob | Remark

|

Published

|

10/01/2024 7:09 PM

|

| 11082 - TA600 Knob removed | Remark

|

Published

|

10/01/2024 7:11 PM

|

| 11078 - 11077 - Prepare for reassembly; Remark: | Procedure Step

|

Published

|

10/01/2024 7:12 PM

|

| 11077 - Prepare for reassembly | Instruction

|

Published

|

10/01/2024 7:12 PM

|

| 11074 - 11073 - Clean top housing; Remark:11071 | Procedure Step

|

Published

|

10/01/2024 7:14 PM

|

| 11073 - Clean top housing | Instruction

|

Published

|

10/01/2024 7:12 PM

|

| 11071 - Use cotton swab and alcohol. Verify surfaces are free of debris, oil, and lub... | Remark

|

Published

|

10/01/2024 7:13 PM

|

| 11072 - TA600 Clean top housing | Remark

|

Published

|

10/01/2024 7:14 PM

|

| 11075 - 11070 - Clean knob; Remark:11068 | Procedure Step

|

Published

|

10/01/2024 7:22 PM

|

| 11070 - Clean knob | Instruction

|

Published

|

10/01/2024 7:15 PM

|

| 11068 - Use cotton swab and alcohol. Verify surfaces are free of debris, oil, and lub... | Remark

|

Published

|

10/01/2024 7:15 PM

|

| 11069 - TA600 Clean knob | Remark

|

Published

|

10/01/2024 7:22 PM

|

| 11076 - 11067 - Lubricate O-ring; Remark:11112 | Procedure Step

|

Published

|

10/01/2024 7:23 PM

|

| 11067 - Lubricate O-ring | Instruction

|

Published

|

10/01/2024 7:23 PM

|

| 11112 - Apply small amount of high viscosity silicone O-ring lubricant to O-ring on p... | Remark

|

Published

|

10/01/2024 7:33 PM

|

| 11113 - TA600 Lubricate O-ring | Remark

|

Published

|

10/01/2024 7:35 PM

|

| 11111 - 11110 - Reinstall power knob; Remark: | Procedure Step

|

Published

|

10/01/2024 7:36 PM

|

| 11110 - Reinstall power knob | Instruction

|

Published

|

10/01/2024 7:36 PM

|

| 11107 - 11105 - Place power knob; Remark:11103 | Procedure Step

|

Published

|

10/01/2024 7:43 PM

|

| 11105 - Place power knob | Instruction

|

Published

|

10/01/2024 7:36 PM

|

| 11103 - Set the power knob onto the switch, but do not press down fully. Leave a gap.... | Remark

|

Published

|

10/01/2024 7:37 PM

|

| 11104 - TA600 Set the power knob onto the switch | Remark

|

Published

|

10/01/2024 7:41 PM

|

| 11108 - 11102 - Insert knob spacer; Remark:11100 | Procedure Step

|

Published

|

10/01/2024 7:46 PM

|

| 11106 - Note : If spacer is not available, use about four (4) sheets of paper, cut to fit aroun... | Annotation

|

Published

|

10/01/2024 7:43 PM

|

| 11102 - Insert knob spacer | Instruction

|

Published

|

10/01/2024 7:44 PM

|

| 11100 - Use 0.01-in. knob spacer. Insert spacer tool between knob and Pager housing. | Remark

|

Published

|

10/01/2024 7:44 PM

|

| 11101 - TA600 Insert knob spacer | Remark

|

Published

|

10/01/2024 7:46 PM

|

| 11109 - 11099 - Seat power knob; Remark:11097 | Procedure Step

|

Published

|

10/01/2024 7:48 PM

|

| 11099 - Seat power knob | Instruction

|

Published

|

10/01/2024 7:47 PM

|

| 11097 - 1 – Verify the O (Off) is aligned with the notch on the instrument. ... | Remark

|

Published

|

10/01/2024 7:47 PM

|

| 11098 - TA600 Seat power knob | Remark

|

Published

|

10/01/2024 7:48 PM

|

| 11137 - 11136 - Apply thread locker; Remark:11134 | Procedure Step

|

Published

|

10/01/2024 7:53 PM

|

| 11136 - Apply thread locker | Instruction

|

Published

|

10/01/2024 7:51 PM

|

| 11134 - 1 – To ease application, place set screw onto 0.05-in. hex driver. 2... | Remark

|

Published

|

10/01/2024 7:52 PM

|

| 11135 - TA600 Apply thread locker | Remark

|

Published

|

10/01/2024 7:53 PM

|

| 11138 - 11132 - Insert set screw; Remark:11129 | Procedure Step

|

Published

|

10/01/2024 7:58 PM

|

| 11133 - Caution : Do not overtighten screw. This will make it difficult to turn power knob. | Annotation

|

Published

|

10/01/2024 7:54 PM

|

| 11132 - Insert set screw | Instruction

|

Published

|

10/01/2024 7:54 PM

|

| 11129 - Use 0.05-in. hex driver. Rotate clockwise. Insert set screw fully into knob. If ... | Remark

|

Published

|

10/01/2024 7:55 PM

|

| 11130 - TA600 Insert set screw, rotate clockwise | Remark

|

Published

|

10/01/2024 7:56 PM

|

| 11131 - TA600 Insert set screw, do not overtighten | Remark

|

Published

|

10/01/2024 7:58 PM

|

| 11139 - 11128 - Remove knob spacer; Remark:11126 | Procedure Step

|

Published

|

10/01/2024 8:00 PM

|

| 11128 - Remove knob spacer | Instruction

|

Published

|

10/01/2024 7:58 PM

|

| 11126 - Slide knob spacer out from under power knob. | Remark

|

Published

|

10/01/2024 7:58 PM

|

| 11127 - TA600 Remove knob spacer | Remark

|

Published

|

10/01/2024 8:00 PM

|

| 11125 - 11124 - Verify instrument is operational; Remark: | Procedure Step

|

Published

|

10/01/2024 8:01 PM

|

| 11124 - Verify instrument is operational | Instruction

|

Published

|

10/01/2024 8:00 PM

|

| 11121 - 11120 - Verify knob alignment; Remark:11118 | Procedure Step

|

Published

|

10/01/2024 8:03 PM

|

| 11120 - Verify knob alignment | Instruction

|

Published

|

10/01/2024 8:01 PM

|

| 11118 - The OFF position (0) should be centered on the notch on the instrument. | Remark

|

Published

|

10/01/2024 8:01 PM

|

| 11119 - TA600 Verify knob alignment | Remark

|

Published

|

10/01/2024 8:02 PM

|

| 11122 - 11117 - Verify knob movement; Remark:11115 | Procedure Step

|

Published

|

10/01/2024 8:05 PM

|

| 11117 - Verify knob movement | Instruction

|

Published

|

10/01/2024 8:03 PM

|

| 11115 - The knob should turn easily. The knob should click into place for vibrate and... | Remark

|

Published

|

10/01/2024 8:03 PM

|

| 11116 - TA600 Verify knob movement | Remark

|

Published

|

10/01/2024 8:05 PM

|

| 11123 - 319 - Perform operational test; Remark:11114 | Procedure Step

|

Published

|

10/01/2024 8:09 PM

|

| 319 - Perform operational test | Instruction

|

Published

|

06/10/2021 8:31 PM

|

| 11114 - DET-HHD-STE-TA6-RM01, TA600 Operational Test | Remark

|

Published

|

10/01/2024 8:09 PM

|

| 322 - 321 - Document maintenance actions; Remark: | Procedure Step

|

Published

|

06/17/2021 9:49 AM

|

| 321 - Document maintenance actions | Instruction

|

Published

|

04/21/2025 11:19 AM

|

| 2869 - 2585 - Document maintenance performed; Remark:2866 | Procedure Step

|

Published

|

06/18/2021 5:58 PM

|

| 2585 - Document maintenance performed | Instruction

|

Published

|

07/09/2021 12:15 PM

|

| 2866 - Record observations, times, and results for the maintenance report. | Remark

|

Published

|

04/21/2025 11:39 AM

|

| 4706 - 4705 - Submit report; Remark:4864 | Procedure Step

|

Published

|

06/29/2022 9:50 AM

|

| 4705 - Submit report | Instruction

|

Published

|

06/29/2022 9:50 AM

|

| 4864 - As specified by management or contractual obligations. | Remark

|

Published

|

07/28/2022 1:36 PM

|

| Corrective Maintenance Procedure | Document Type

|

Published

|

03/02/2020 3:32 PM

|

| minutes | Duration

|

Published

|

05/26/2022 11:41 AM

|

| Power knob is difficult to turn | Frequency

|

Published

|

10/02/2024 6:09 AM

|

| As Needed | Frequency

|

Published

|

04/01/2020 11:36 AM

|

| Note | Annotation Type

|

Published

|

03/02/2020 3:25 PM

|

| Caution | Annotation Type

|

Published

|

03/02/2020 3:24 PM

|

| Technician 2 | Skill Level

|

Published

|

04/09/2020 1:17 AM

|

| 0.05-in. hex driver | Replacement Parts

|

Published

|

10/01/2024 7:27 PM

|

| Knob spacer, 0.01-in. U-shaped shim | Replacement Parts

|

Published

|

10/01/2024 7:27 PM

|

| Small slotted screwdriver | Replacement Parts

|

Published

|

10/01/2024 7:27 PM

|

| TA600 Verify Knob Alignment | Image

|

Published

|

10/01/2024 7:27 PM

|

| Remove set screw | Image

|

Published

|

10/01/2024 7:27 PM

|

| Retain set screw. | Image

|

Published

|

10/01/2024 7:27 PM

|

| TA600 Remove knob | Image

|

Published

|

10/01/2024 7:27 PM

|

| TA600 Carefully pry up the knob | Image

|

Published

|

10/01/2024 7:27 PM

|

| TA600 Knob removed | Image

|

Published

|

10/01/2024 7:27 PM

|

| TA600 Clean top housing | Image

|

Published

|

10/01/2024 7:27 PM

|

| TA600 Clean knob | Image

|

Published

|

10/01/2024 7:27 PM

|

| TA600_Lubricate O-Rrng_0.png | Image

|

Published

|

10/02/2024 9:00 AM

|

| TA600 Set the power knob onto the switch | Image

|

Published

|

10/01/2024 7:50 PM

|

| TA600 Insert knob spacer | Image

|

Published

|

10/01/2024 7:50 PM

|

| TA600 Seat power knob | Image

|

Published

|

10/01/2024 7:50 PM

|

| TA600 Apply thread locker | Image

|

Published

|

10/01/2024 8:20 PM

|

| TA600 Insert set screw, rotate clockwise | Image

|

Published

|

10/01/2024 8:20 PM

|

| TA600_Insert_Set_Screw_do_not_overtighten.png | Image

|

Published

|

10/01/2024 8:33 PM

|

| TA600 Remove knob spacer | Image

|

Published

|

10/01/2024 8:20 PM

|

| TA600 Verify knob alignment | Image

|

Published

|

10/01/2024 8:20 PM

|

| TA600 Verify knob movement | Image

|

Published

|

10/01/2024 8:20 PM

|

This procedure provides instructions for repairing power knobs that are too stiff to turn. If the instrument also has a display button that is too difficult to press, then the entire top housing should be replaced; refer to DET-HHD-STE-TA6-CM02, TA600 Top Housing Replacement. The 0.05-in. [inch] hex driver needed to perform this procedure is not a commonly available tool and should be obtained in advance of attempting this procedure. It is also recommended to use a magnifying glass as the components are very small.

Prior to arrival, notify operators concerning expected work and duration.

11095 - 313 - Power off instrument; Remark:11093

313 - Power off instrument

Power off instrument

11093 - Rotate switch to OFF position.

Rotate switch to OFF position.

11092 - 11091 - Uninstall power knob; Remark:

11091 - Uninstall power knob

Uninstall power knob

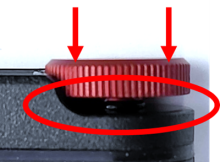

11089 - 11088 - Remove set screw; Remark:11084

11088 - Remove set screw

Remove set screw

11084 - Use 0.05-in. hex driver. Rotate counterclockwise.

Use 0.05-in. hex driver. Rotate counterclockwise.

11085 - Remove set screw

11086 - Retain set screw.

Retain set screw.

11087 - Retain set screw

11090 - 11083 - Remove knob; Remark:11079

11083 - Remove knob

11079 - If needed, use small, slotted screwdriver. Carefully pry up the knob using small...

11078 - 11077 - Prepare for reassembly; Remark:

11077 - Prepare for reassembly

Prepare for reassembly

11074 - 11073 - Clean top housing; Remark:11071

11073 - Clean top housing

Clean top housing

11071 - Use cotton swab and alcohol. Verify surfaces are free of debris, oil, and lub...

Use cotton swab and alcohol. Verify surfaces are free of debris, oil, and lubricants.

11075 - 11070 - Clean knob; Remark:11068

11070 - Clean knob

Clean knob

11068 - Use cotton swab and alcohol. Verify surfaces are free of debris, oil, and lub...

Use cotton swab and alcohol. Verify surfaces are free of debris, oil, and lubricants.

11069 - TA600 Clean knob

11076 - 11067 - Lubricate O-ring; Remark:11112

11067 - Lubricate O-ring

Lubricate O-ring

11112 - Apply small amount of high viscosity silicone O-ring lubricant to O-ring on p...

Apply small amount of high viscosity silicone O-ring lubricant to O-ring on power knob.

11111 - 11110 - Reinstall power knob; Remark:

11110 - Reinstall power knob

Reinstall power knob

11107 - 11105 - Place power knob; Remark:11103

11105 - Place power knob

Place power knob

11103 - Set the power knob onto the switch, but do not press down fully. Leave a gap....

Set the power knob onto the switch, but do not press down fully. Leave a gap.

11108 - 11102 - Insert knob spacer; Remark:11100

11106 - Note : If spacer is not available, use about four (4) sheets of paper, cut to fit aroun...

11102 - Insert knob spacer

Insert knob spacer

11100 - Use 0.01-in. knob spacer. Insert spacer tool between knob and Pager housing.

11109 - 11099 - Seat power knob; Remark:11097

11099 - Seat power knob

Seat power knob

11097 - 1 – Verify the O (Off) is aligned with the notch on the instrument. ...

1 – Verify the O (Off) is aligned with the notch on the instrument.

2 – Press the power knob down on to the instrument.

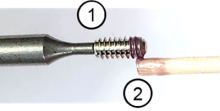

11137 - 11136 - Apply thread locker; Remark:11134

11136 - Apply thread locker

11134 - 1 – To ease application, place set screw onto 0.05-in. hex driver. 2...

1 – To ease application, place set screw onto 0.05-in. hex driver.

2 – Use a swab stick to apply thread locker to the bottom threads of set screw.

11138 - 11132 - Insert set screw; Remark:11129

11133 - Caution : Do not overtighten screw. This will make it difficult to turn power knob.

11132 - Insert set screw

11129 - Use 0.05-in. hex driver. Rotate clockwise. Insert set screw fully into knob. If ...

11139 - 11128 - Remove knob spacer; Remark:11126

11128 - Remove knob spacer

Remove knob spacer

11126 - Slide knob spacer out from under power knob.

Slide knob spacer out from under power knob.

11125 - 11124 - Verify instrument is operational; Remark:

11124 - Verify instrument is operational

Verify instrument is operational

11121 - 11120 - Verify knob alignment; Remark:11118

11120 - Verify knob alignment

Verify knob alignment

11118 - The OFF position (0) should be centered on the notch on the instrument.

11122 - 11117 - Verify knob movement; Remark:11115

11117 - Verify knob movement

11115 - The knob should turn easily. The knob should click into place for vibrate and...

The knob should turn easily. The knob should click into place for vibrate and audible modes.

11123 - 319 - Perform operational test; Remark:11114

319 - Perform operational test

Perform operational test

11114 - DET-HHD-STE-TA6-RM01, TA600 Operational Test

DET-HHD-STE-TA6-RM01, TA600 Operational Test

322 - 321 - Document maintenance actions; Remark:

321 - Document maintenance actions

Document maintenance actions

2869 - 2585 - Document maintenance performed; Remark:2866

2585 - Document maintenance performed

Document maintenance performed

2866 - Record observations, times, and results for the maintenance report.

Record observations, times, and results for the maintenance report.

4706 - 4705 - Submit report; Remark:4864

4705 - Submit report

Submit report

4864 - As specified by management or contractual obligations.

As specified by management or contractual obligations.