Last Updated: 04/24/2025 1:44 AM

The following table lists all the components that make up the document.

Replace SCA-774 Single Channel Analyzer (SCA) board.

Coordinate access with system operators

7478 - 1401 - Establish Initial Conditions; Remark:

1401 - Establish Initial Conditions

Establish Initial Conditions

7823 - 7592 - Inform system operators; Remark:

7592 - Inform system operators

Inform system operators

7824 - 7676 - Brief system operators on expected work, duration, anticipated alarms, and fa...; Remark:7677

7676 - Brief system operators on expected work, duration, anticipated alarms, and fa...

Brief system operators on expected work, duration, anticipated alarms, and fault indications before starting work

7677 - Operators should expect numerous fault indications and alarms during procedur...

Operators should expect numerous fault indications and alarms during procedure.

7825 - 7594 - Close lane and set up barriers to establish a safety watch; Remark:7595

7678 - Warning : Traffic should temporarily be rerouted or halted during conduction of this pr...

Traffic should temporarily be rerouted or halted during conduction of this procedure to ensure maintenance provider safety and prevent unscreened conveyances from passing.

7594 - Close lane and set up barriers to establish a safety watch

Close lane and set up barriers to establish a safety watch

7595 - Use orange safety (traffic control) cones or equivalent per site-specific saf...

Use orange safety (traffic control) cones or equivalent per site-specific safety practices.

7270 - 7235 - Power off RPM; Remark:7236

7235 - Power off RPM

Power off RPM

7236 - Move LD-260 switch to OFF position. The PWR ON

Move LD-260 switch to OFF position. The PWR ON LED will turn off.

7827 - 7791 - Remove SCA-774 Board; Remark:

7791 - Remove SCA-774 Board

Remove SCA-774 Board

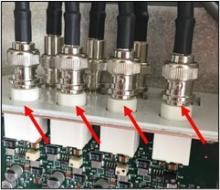

7828 - 7793 - Disconnect only signal (BNC) cables from SCA-775 module; Remark:7794

7792 - Note : It is good engineering practice to ensure all cables and connectors are label...

It is good engineering practice to ensure all cables and connectors are labeled before disconnecting them.

7793 - Disconnect only signal (BNC) cables from SCA-775 module

Disconnect only signal (BNC) cables from SCA-775 module

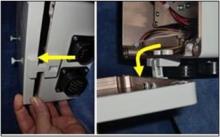

7829 - 7796 - Loosen screws in each corner (4) using medium Philips screwdriver and open SC...; Remark:7797

7795 - Caution : If you rotate cover of the SCA-775 down without first pulling out from the bo...

If you rotate cover of the SCA-775 down without first pulling out from the box, the hinge will break.

7796 - Loosen screws in each corner (4) using medium Philips screwdriver and open SC...

Loosen screws in each corner (4) using medium Philips screwdriver and open SCA-775 module

7797 - Normally the cover screws are captured and should not come out of cover. ...

Normally the cover screws are captured and should not come out of cover.

9467 - To prevent breaking the hinge on the module / door, once the retainer screws ...

To prevent breaking the hinge on the module / door, once the retainer screws are loosened, take care to gently pull the bottom of the cover away from the module approximately ¼ʺ before letting the door open.

7830 - 7799 - Disconnect 4 wiring harness assembly/connectors (J6, J8, J10, J11) from SCA-7...; Remark:7800

7798 - Caution : Never remove connectors by pulling on wires.

Never remove connectors by pulling on wires.

7792 - Note : It is good engineering practice to ensure all cables and connectors are label...

It is good engineering practice to ensure all cables and connectors are labeled before disconnecting them.

7799 - Disconnect 4 wiring harness assembly/connectors (J6, J8, J10, J11) from SCA-7...

Disconnect 4 wiring harness assembly/connectors (J6, J8, J10, J11) from SCA-774 board

7800 - J8 and J11 should be labeled; write J6 and J10 on the appropriate connector i...

J8 and J11 should be labeled; write J6 and J10 on the appropriate connector in permanent marker.

J8 and J11 should be easily removed by grasping the connector and pulling it out with a gentle rocking motion.

J10 is locked in place by the position of J6; remove J6 first.

7831 - 7801 - Remove 4 screws at corners of board; Remark:7802

7801 - Remove 4 screws at corners of board

Remove 4 screws at corners of board

7802 - Do not lose the screws. They are re-used to secure the SCA-774 board.

Do not lose the screws. They are re-used to secure the SCA-774 board.

7832 - 7803 - Remove board from SCA-775 module; Remark:7804

7803 - Remove board from SCA-775 module

Remove board from SCA-775 module

7804 - BNC connectors are attached to the SCA-774 board and easily slide down then o...

BNC connectors are attached to the SCA-774 board and easily slide down then out of the SCA-775 box.

3397 - 3395 - Contrassegnare il componente difettoso; Remark:3396

3395 - Contrassegnare il componente difettoso

Contrassegnare il componente difettoso

3396 - Utilizzare un'etichetta o un nastro adesivo. Indicare la data di rimozione, la d...

Utilizzare un'etichetta o un nastro adesivo. Indicare la data di rimozione, la descrizione del guasto, il Paese, il sito e il numero di corsia. Smaltire secondo la guida del Nuclear Smuggling Detection and Deterrence (NSDD) o i requisiti contrattuali.

7833 - 7805 - Install New SCA-774; Remark:

7805 - Install New SCA-774

Install New SCA-774

7834 - 7806 - Install new SCA-774 board; Remark:7807

7806 - Install new SCA-774 board

Install new SCA-774 board

7807 - Use screws previously removed.

Use screws previously removed.

7835 - 7809 - Reconnect 4 wiring harness assembly/connectors (J6, J8, J10, J11) from SCA-77...; Remark:7810

7808 - Caution : Proper connection of wiring harnesses is critical.

Proper connection of wiring harnesses is critical.

7809 - Reconnect 4 wiring harness assembly/connectors (J6, J8, J10, J11) from SCA-77...

Reconnect 4 wiring harness assembly/connectors (J6, J8, J10, J11) from SCA-774 board

7810 - Ensure all pins are engaged. It is easy to install the connectors one pin off...

Ensure all pins are engaged. It is easy to install the connectors one pin off in either direction.

7836 - 7813 - Reconnect BNC connectors on top of SCA-775 module; Remark:

7811 - Caution : Proper connection of cables is critical.

Proper connection of cables is critical.

7813 - Reconnect BNC connectors on top of SCA-775 module

Reconnect BNC connectors on top of SCA-775 module

7837 - 7814 - Close SCA-775 module cover and tighten 4 screws; Remark:7815

7814 - Close SCA-775 module cover and tighten 4 screws

Close SCA-775 module cover and tighten 4 screws

7815 - If the follow-on alignment and functional compliance test procedures are to b...

If the follow-on alignment and functional compliance test procedures are to be completed immediately, there is no need to close the SCA-775 module cover; if not, close the cover and tighten the screws.

7280 - 7250 - Power on RPM; Remark:7251

7250 - Power on RPM

Power on RPM

7251 - Move LD-260 switch to ON position. The LED PWR ON

Move LD-260 switch to ON position. The LED PWR ON will illuminate.

7281 - 7252 - Verify RPM start-up; Remark:7253

7252 - Verify RPM start-up

Verify RPM start-up

7253 - RPM will perform a power on self-test (POST) and collect a background radiati...

RPM will perform a power on self-test (POST) and collect a background radiation measurement.

7279 - 7249 - Return equipment to normal operating condition; Remark:

7249 - Return equipment to normal operating condition

Return equipment to normal operating condition

7840 - 7816 - Perform electronic alignment; Remark:7817

7816 - Perform electronic alignment

Perform electronic alignment

7817 - DET-RPM-RAP-CM01, RPM Electronic Alignment Procedure.

DET-RPM-RAP-CM01, RPM Electronic Alignment Procedure.

7842 - 7820 - Inform system operators upon completion of maintenance action; Remark:

7820 - Inform system operators upon completion of maintenance action

Inform system operators upon completion of maintenance action

322 - 321 - Documentare le attività di manutenzione; Remark:

321 - Documentare le attività di manutenzione

Documentare le attività di manutenzione

2869 - 2585 - Documentare la manutenzione eseguita; Remark:2866

2585 - Documentare la manutenzione eseguita

Documentare la manutenzione eseguita

2866 - Annotare le osservazioni e i risultati per il Rapporto di manutenzione correttiv...

Annotare le osservazioni e i risultati per il Rapporto di manutenzione correttiva.

4706 - 4705 - Inoltrare il report; Remark:4864

4705 - Inoltrare il report

Inoltrare il report

4864 - Inviare il file di valutazione HATS elettronicamente con il Rapporto di manutenz...

Inviare il file di valutazione HATS elettronicamente con il Rapporto di manutenzione ordinaria.